Honoring a Sefi-Intrafor site in Gagny in the department of Seine-Saint-Denis (93).

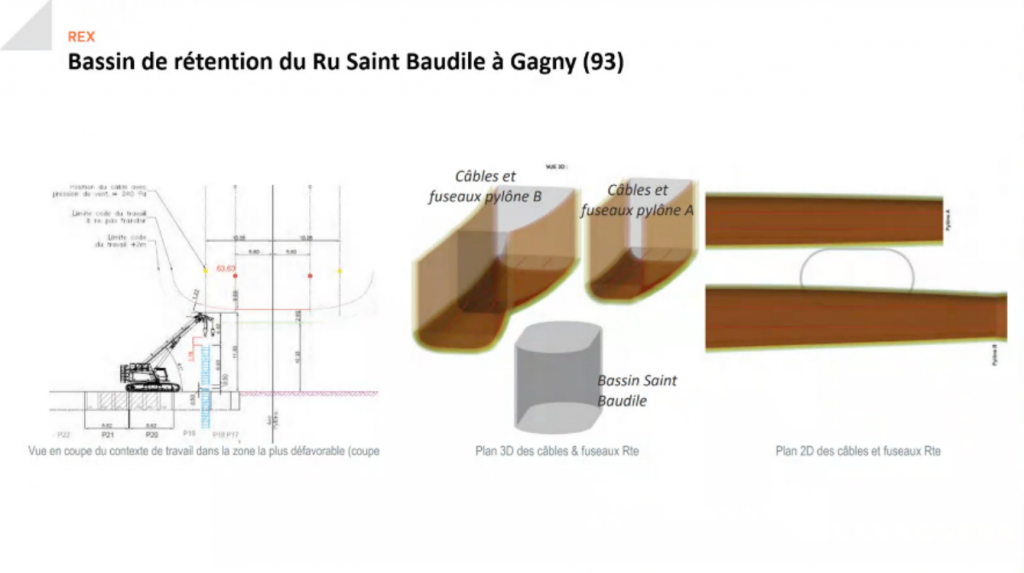

As part of the 2024 Olympics, CAD.42 recently worked on the Sefi-Intrafor site in Gagny in the department of Seine-Saint-Denis (93). This project consists of the construction of a rainwater retention basin in a site marked by the presence of very high voltage lines of 225 volts which are, at the lowest, 10 meters from the ground. It was necessary to set up virtual safety barriers in relation to the position of the cables.

CAD.42's RTK.42 system is implemented to help crane operators respect established safety zones.

Context

The risk that arises on this site is the presence of HT lines and cranes that can measure up to 17 meters in height used to excavate the ground in order to create a deep diaphragm wall.

The difficulty for these machines will be the lack of height since they are located below the lines whose lowest point is 10 meters from the ground. The challenge is therefore to ensure that the machines respect the safety limit zones.

The CAD.42 solution implemented

CAD.42 then intervened to integrate the RTK.42 solution on the site. The optimization of productivity and safety has gone through the creation of different zones or 3D virtual barriers.

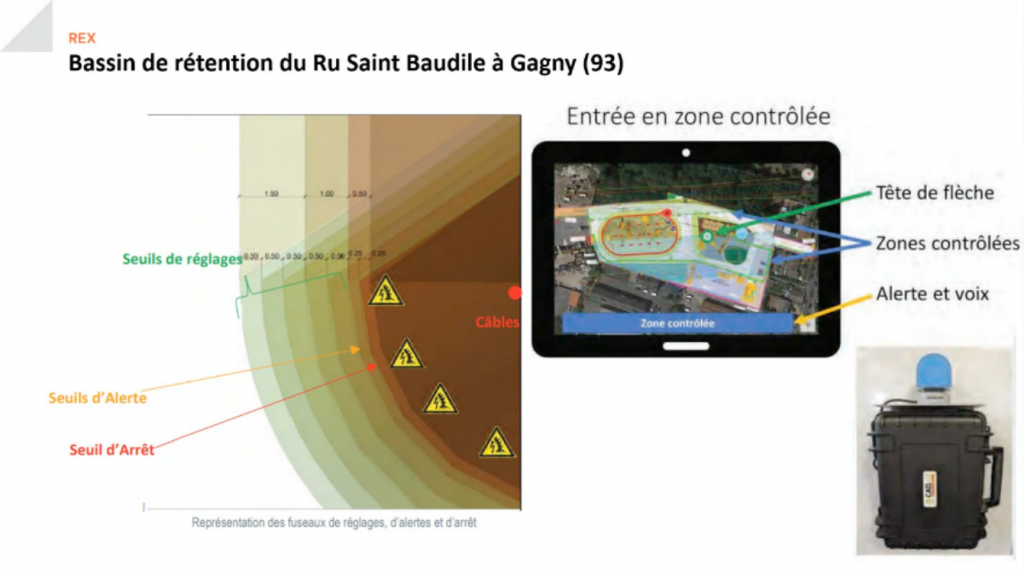

The alert or information zones were composed of:

- A security zone of 5 meters where it is forbidden to enter,

- 5 alert and stop zones spaced 50 centimeters apart,

- 2 distinct zones, one controlled and one free.

These spindles ensure safety and establish a final position before being able to work on the entire site.

To do this, the RTK.42 sensor was installed on the jib heads of mobile and drilling cranes. Its centimetric GPS sensor made it possible to check the position of the equipped machines in relation to the spindles in a precise manner. The data is uploaded in real time to the CAD.42 web platform which will analyze to alert both the crane operators via a tablet in the cabin but also the supervisors by text message or email. The platform makes it possible to log all near misses for continuous analysis.

RTK.42, centimeter sensor

RTK.42 magnetizes to the boom head of the mobile crane. The absolute height is calculated with centimeter precision every second. One-week battery life allows for daily, continuous use.

Tablet with map and alerts

The tablet informs the crane operator when entering prohibited areas with an audible and visual signal.

How it works ?

The tablet informs the crane operator when the height of the jib head approaches the safety spindles by a voice message. In the immediate vicinity of the threshold, an audible alert replaces the voice message to signify the immediate danger. A gyrosiren is mounted on each crane to warn ground teams of any danger. All alerts are logged and viewable on the Unifield online application.

Conclusion

“The project is successful, we have never entered the prohibited areas. This is essential from a security point of view. On the production side, we were in line with our initial predictions, everything went as on paper. […] In a future project where there will be aerial constraints, we have a solution that works. ” Florian Nibel, site supervisor at Fayat